sheet metal part design ppt Sheet metal design. - The document provides instructions for using CATIA's Sheet Metal Design workbench to design sheet metal parts. - It begins with an overview and getting . Metal stamping is the manufacturing process in which a strip of sheet metal is fed through one or more die and tool sets to apply pressure, re-forming and cutting the piece into a desired shape.

0 · sheet metal stamping process pdf

1 · sheet metal manufacturing process ppt

2 · sheet metal calculations pdf

3 · sheet metal bending machine ppt

4 · sheet metal basic ppt

5 · sheet metal basic drawing

6 · rolling direction of sheet metal

7 · mechanical properties of sheet metal

Rembar offers custom fabrication of metal parts and components using refractory metal including Molybdenum, Tantalum, Tungsten, and Niobium in sheet, plate, wire, rod, and tube form.

The document discusses various sheet metal processes including bending, shearing, staking, and stamping. It provides details on: - How bending changes the shape of .This document provides information on sheet metal design and manufacturing .

This document provides an overview of sheet metal modeling techniques in . This document provides information on sheet metal design and manufacturing processes. It discusses parameters for sheet metal like thickness and common terminology. It also outlines various sheet metal processes like . Sheet metal design. - The document provides instructions for using CATIA's Sheet Metal Design workbench to design sheet metal parts. - It begins with an overview and getting . Chapter 10 - Objectives • After completing this chapter, you will be able to perform the following: • Start the Autodesk Inventor sheet metal .

sheet metal stamping process pdf

Chapter 10 - Objectives After completing this chapter, you will be able to perform the following: Start the Autodesk Inventor sheet metal environment Modify settings for sheet metal design .

key fob metal box

The document provides an overview of sheet metal design, including the metals used, gauges, common forming processes like bending and punching, die manufacturing, design calculations for processes like blanking and drawing, .Sheet Metal Design - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document provides information on sheet metal design and manufacturing processes.

In this guide, we delve into the principles of sheet metal design, provide technical insights, and share essential guidelines to help you navigate the world of sheet metal fabrication with confidence.Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication . This document provides an overview of sheet metal modeling techniques in SolidWorks. It covers sheet metal theory, tools, bend and gauge tables, advanced forming shapes, creating forming tools, sheet metal .

5. Introduction (CONTD.) • The Progressive die or transfer die is dependent on size, complexity and volume of production. Progressive die stamping is used to produce a large number of parts and keep the costs as . The first step in creating a sheet metal part is sheet metal design. This process starts with an idea or concept that is then turned into a detailed 3D model using Computer-Aided Design (CAD) software. This 3D model includes .Biw Design - Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. The document provides an introduction to body-in-white (BIW) design, outlining the different types of .Below you’ll see thumbnail sized previews of the title slides of a few of our 169 best sheet metal templates for PowerPoint and Google Slides. The text you’ll see in in those slides is just example text. The sheet metal-related image or video you’ll see in the background of each title slide is designed to help you set the stage for your .

If you design sheet metal parts, you may know that bend relief is a notch cut made into the . Continuing our focus on sheet metal forming, this issue of DFM guidebook focuses on design guidelines for bend relief parameters, distance between holes and bends and offset bend material when a bend is made close to an edge. .We follow Sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. As a result, you can deliver the product at a low cost and faster timeline. It is difficult to follow all sheet metal design guidelines for complex sheet metal parts. Therefore exceptions can be there for complex sheet metal parts. 12. Sheet metal parts are usually made by forming material in a cold condition , although many sheet metal parts are in a hot condition because the material when heated has a lower resistance to the deformation. Spring or blanks are very often used as initial materials, and are formed on press using appropriate tools. The shape of the part generally corresponds to .

Ppt on catia - Download as a PDF or view online for free. . It provides tools for sketching, part design, sheet metal design, and more. Key features include the specification tree to view a part's design history, assembly design tools to combine parts while defining relationships and constraints, and surface modeling tools for complex shapes. . Chapter 10 Sheet Metal Design . Chapter 10 - Objectives. After completing this chapter, you will be able to perform the following: Start the Autodesk Inventor sheet metal environment Modify settings for sheet metal design Create .

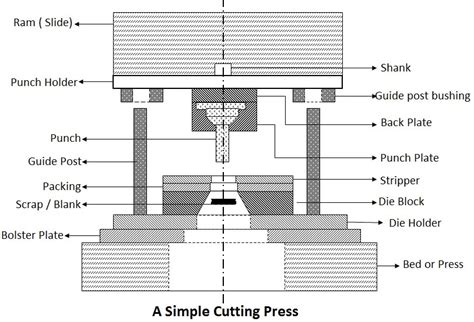

As sheet metal parts are fabricated from one sheet of metal, the part must maintain uniform wall thickness throughout. We recommend a sheet metal thickness range between 0.5-10 mm (0.02-0.394 in) for laser cutting and 0.5-6 mm (0.02-0.236 in) for bending. Punch: The tool typically attached to the upper portion of the die set that shapes or penetrates the sheet metal. Punch press: A machine with a stationary base and an upper ram that moves along a vertical axis to shear, bend, or form sheet metal. 4. Chapter 9 Sheet Metal Design . Chapter 9 - Objectives. After completing this chapter, you will be able to Start the Autodesk Inventor sheet metal environment Modify settings for sheet metal design Create sheet metal parts Modify sheet metal parts to match design requirements Slideshow 1262043. An Image/Link below is provided (as is) to download presentation Download Policy: . Start the Autodesk Inventor sheet metal environment Modify settings for sheet metal design Create sheet metal parts. 2.28k views • 43 slides. CHAPTER 6 SHEET METAL WORKING PROCESSES. ME 333 PRODUCTION PROCESSES II. CHAPTER 6 SHEET METAL .

If you design your sheet metal part as a solid object, it’s important that you send us a CAD file that appears folded, but shows where bends should go. Related to this, because the raw materials are single sheets of metal, the entire part must have the same material thickness throughout. For example, if you create a part that uses 0.125 in .Geomiq's Sheet Metal design guide helps you with your design process to accelerate production time and reduce production costs. Geomiq’s digital manufacturing platform makes rapid prototype and production manufacturing .

3MET3331, Prof Simin Nasseri, Part 2 Southern Polytechnic State University Die Cutting Operation Cutting and forming operations performed on relatively thin sheets of metal Thickness of sheet metal = 0.4 mm (1/64 in) to 6 . 11. Sheet Metal operations Introduction Sheet metal formingis a grouping of many complementary processes that are used to form sheet metal parts. One or more of these processes is used to take a flat sheet of ductile . Best sheet metal fabrication in China. Sheet metal is a kind of integrated metal cold working technology for metal sheet (usually in under 6mm), usually the parts plastically deformed by handwork or stamping die to form your desired shape and size, and it also can be further formed more complex parts by welding or other metal cold working technology, . Shear Spinning • A sheet metal blank is placed between the mandrel and the tailstock of the spinning machine. The mandrel has the interior shape of the desired final component. • A roller makes the sheet metal wrap the mandrel so that it takes its shape. • As can be seen, s1 which is the initial wall thickness of the work piece is reduced .

geometries, the user has the option to use non-sheet metal feature tools and then use the Insert Bends or “Convert to Sheet Metal” features. When designing with sheet metal, it is important to think about the best approach to model or design a part. At times, it may appear quicker to use non-sheet metal features (boss-extrude, Press tools are commonly used in hydraulic, pneumatic, and mechanical presses to produce the sheet metal components in large volumes. Generally press tools are categorized by the types of operation performed using the tool, such as blanking, piercing, bending, forming, forging, trimming etc.Press tools are commonly used in hydraulic, pneumatic, and mechanical .

2. CUTTING ACTION IN A DIE The cutting action of sheet metal in press work is a shearing process. Blanking and piercing operations are performed to prepare stock for further processing. The punch is of same shape as of die opening except that it is smaller on each side by an amount known as clearance. as the punch touches the material and travels downwards, . 14. (iv) Power shearing: This operation is carried out on power shearing machines where in the stock material (plate or sheet metal) is cut between the two cutting blades in the form of dies. The lower cutting blade is fixed and the upper cutting blade is movable and it is set at slight angle to the edge of the stationary blade. (v) Cutting off: In this operation a piece is .Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. Set a value for Bend Radius.; Under Bend Allowance, select from: Bend Table, K-Factor, Bend Allowance, Bend Deduction, .

Sheet Metal Design - Download as a PDF or view online for free. . After all, we are the widely acknowledged as well as the proven experts in Catia 3D aircraft components and parts design and catia airplane models structure services including providing the best Catia 3D aircraft modeling services possible. The document provides notes from a training course on aerospace sheet metal design using CATIA. It includes an introduction, overview of the ASL workbench interface, descriptions of how to set parameters and load design data, and step-by-step instructions for various sheet metal design features such as creating a web, surfacic flanges, joggles, cutouts, .

Sheet Metal Design - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document provides information on sheet metal design and manufacturing processes. It discusses what sheet metal is and lists common sheet metal operations which are divided into cutting processes like shearing, blanking, piercing, and .

Rembar offers custom fabrication of metal parts and components using refractory metal including Molybdenum, Tantalum, Tungsten, and .

sheet metal part design ppt|sheet metal basic drawing